Railroad applications

Railroad applications demand high availability and a high level of safety for the hardware and software. SYS TEC electronic has been developing electronic assemblies for this industry on behalf of customers for several years and has built up know-how for various solutions:

Examples:

- Communication computers with interfaces for Gbit-Ethernet, CAN, RS485, WLAN, GSM, LTE, GPS.

- Power supplies with wide input voltage range 16.8VDC - 160VDC

- Embedded controllers for functional safety applications

- IO modules for digital and precise analog interfaces

We take over the development of your hardware and software according to the standards for railroad applications (EN50126, EN50155, EN50128, EN50129) and manufacture them as series products at our site. In the railroad sector, high availability and long product life are important. Accordingly, the demands on the hardware and software of electronic assemblies are usually higher. This is reflected in larger temperature ranges, higher immunity to EMC phenomena, robust design of the electronics and larger insulation distances for altitudes up to 5000m. In addition to these high product requirements, significantly increased demands on the development process for hardware and software must also be implemented.

Starting point for the development of a product at SYS TEC electronic are clearly formulated requirements for the system, which we receive from our customers. We support our customers in creating them by applying requirements engineering techniques. The requirements are captured and managed using the requirements management tool Polarion. For each requirement, tests are linked for analysis and validation, and test executions are then planned and executed for multiple tests. The results are also stored in Polarion. When requirements or system components change, the impact is easily identified when the impact analysis is performed.

Applications for the railroad sector are characterized by a long life cycle of more than 20 years. Here it is important to have good and traceable documentation for the designs. When components are discontinued, it is important to know the key parameters and properties of the obsolete component or the affected circuit part in order to create replacements with comparable properties.

In software design, we use proven techniques to avoid errors at the coding stage. To support the longer lifecycle and to achieve good traceability, SW requirements from the requirements management tool are directly linked to the line of code in the software. Changes to the software are documented in the version management tool git in a traceable manner.

The design phase is followed by an extensive verification phase. Through a phased approach to execution, we achieve high test coverage for the design and specified requirements. In the software area, we use techniques known from the field offunctional safety. These tests are supported by various tools for static code analysis, unit tests and continuous integration. All these techniques are used with the aim of detecting errors at an early stage.

In our in-house EMC lab, we perform all conducted immunity tests on the prototype assemblies to verify the robustness of the design. Additional EMC, environmental and vibration testing for certification of the devices is performed in external laboratories.

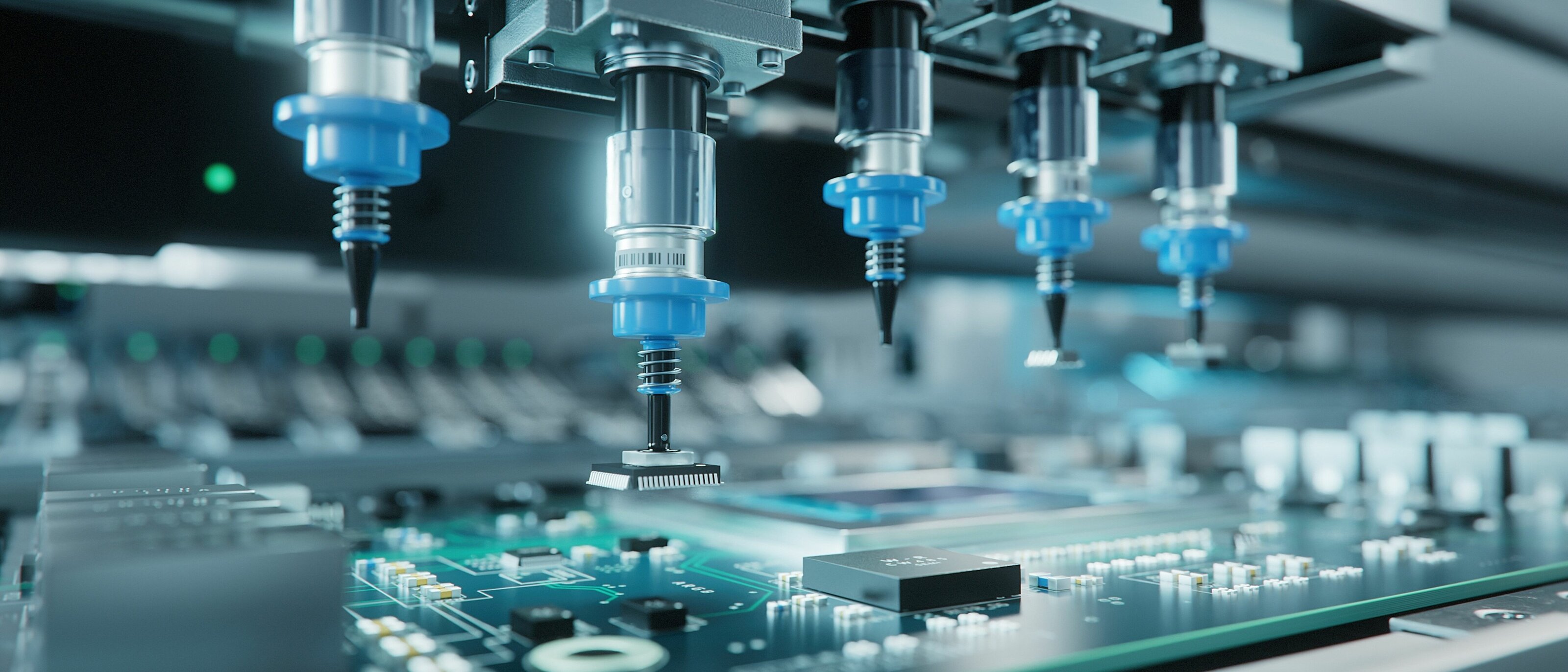

The assemblies are manufactured in our production facility in Germany, starting with SMD and THT assembly, through to painting, potting, assembly and packaging. We attach great importance to a high test coverage through various test steps, such asAOI,ICT,HV test, functional tests,burn-in in our climate chamber.