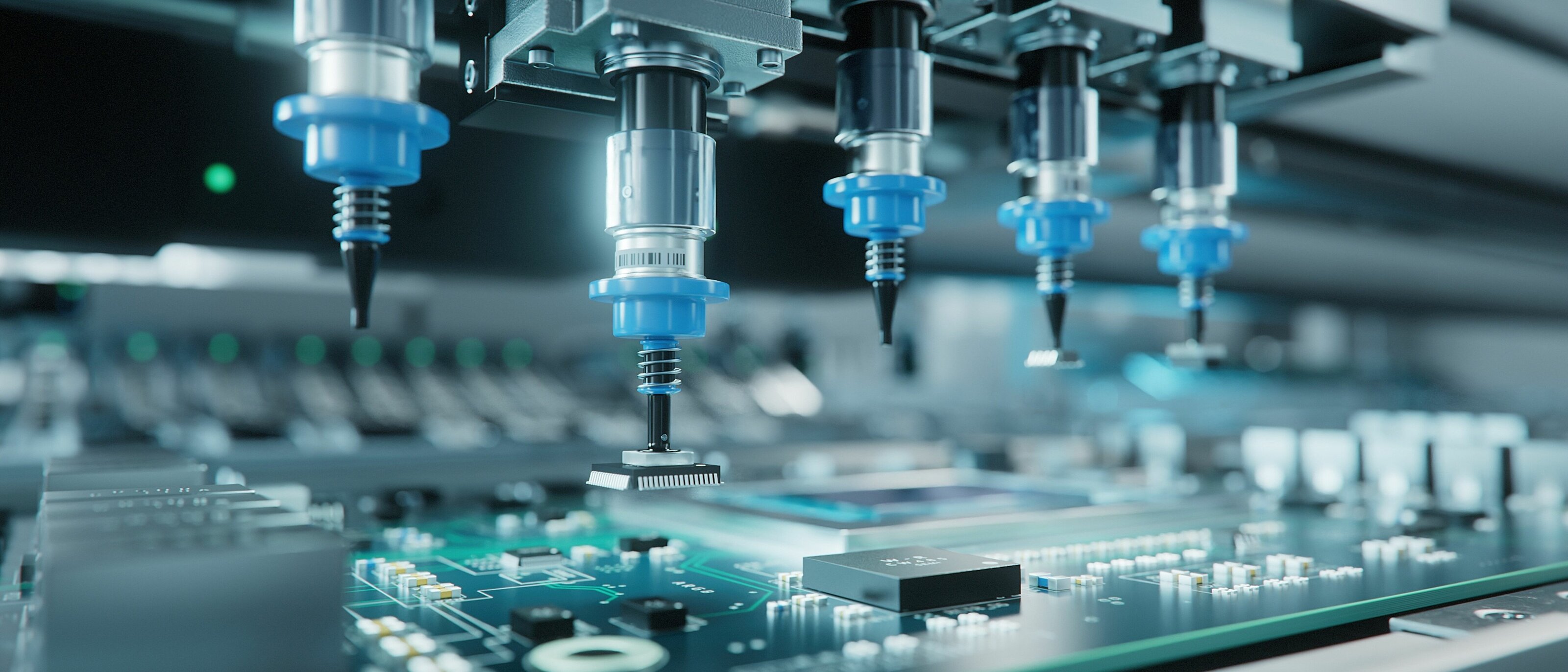

IoT application with in-house hardware in electronics manufacturing

We have expanded our own electronics production with a new Internet of Things application with in-house devices and thus further expanded our demo range again. This gives our customers and partners the opportunity to monitor their production as well, to detect possible failures at an early stage and to be able to act in time.

In the age of the Internet of Things, production processes are networked via intelligent individual components. Our IoT complete package enables the retrofit of your existing machines and raises them to the Industry 4.0 level. This allows maintenance intervals to be optimized in terms of predictive maintenance and condition monitoring and ultimately saves costs. Thus, the production manager has an overview of all important processes, is informed about errors (e.g. temperature drop or moisture loss) via an early warning system and is able to act promptly. In addition, machine signals and power consumption can be monitored. The latter, in particular, enables peak shaving and thus a reduction in costs.

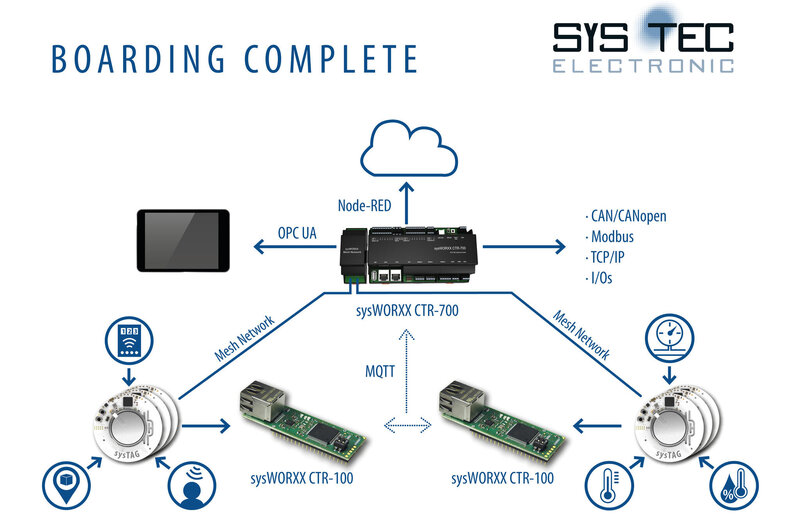

For this application, a variable, intelligent network is set up using sensor beacons and asset tracking beacons, among other things, which manages with the smallest amounts of data and sends them to the gateway. The special feature here is the use of our own hardware. With the help of our in-house sysWORXX CTR-100 and CTR-700 controllers, which act as controllers with gateway function, the data from the beacons can be recorded, processed and sent. The visualization of the data is done by Node-RED.

We also equip your production with our innovative IoT hardware - and all this without any confusing cabling effort. This way, you can also save costs and resources in terms of predictive maintenance.