Interview: From sensor to human and back

Interview: Fanny Seifert, ELCO Industrie Automation

As a system integrator in a networked world, SYS TEC electronic works with several partners. In our interview series, we introduce the partners and their know-how.

Fanny Seifert from our partner ELCO Industrie Automation talks about Industrial IoT, the challenges and economic benefits of IIoT as well as the cooperation with SYS TEC electronic:

What is IIoT?

I understand the Industrial Internet of Things as the possibility of networking the most diverse "things" in industry such as machines, measuring devices, components, sensors, finished products, etc. and also people with each other via the Internet in order to generate individual added value.

How can communication between people and machines succeed?

It is very important to involve people with their knowledge and experience. The data must not just go from the sensor to the cloud, but to the human being and back.

On the one hand, a translator is needed that understands the languages of the machines and processes them for humans, e.g., a platform like the IoTHub that translates the language of the machines for humans and vice versa. On the other hand, a medium is needed through which machines and humans can communicate. Industrial apps, for example, are suitable for this purpose, which humans can use on the tablet or smartphone that almost everyone now carries with them to interact with the machine.

It is important that these translators and media can be adapted individually for each use case, i.e. for each machine and each person. With the right tools, this can be done quite easily.

To what extent does IIoT contribute to value creation?

Thanks to the possibility of IIoT, companies gain more transparency about their processes, can find out optimization potential and make these processes more efficient. In addition, networking can automate processes, saving resources and simplifying processes. In some cases, the new added values created with the help of IIoT can become entirely new "digital products" of their own. In the end, costs can be saved or more revenue generated with the help of IIoT.

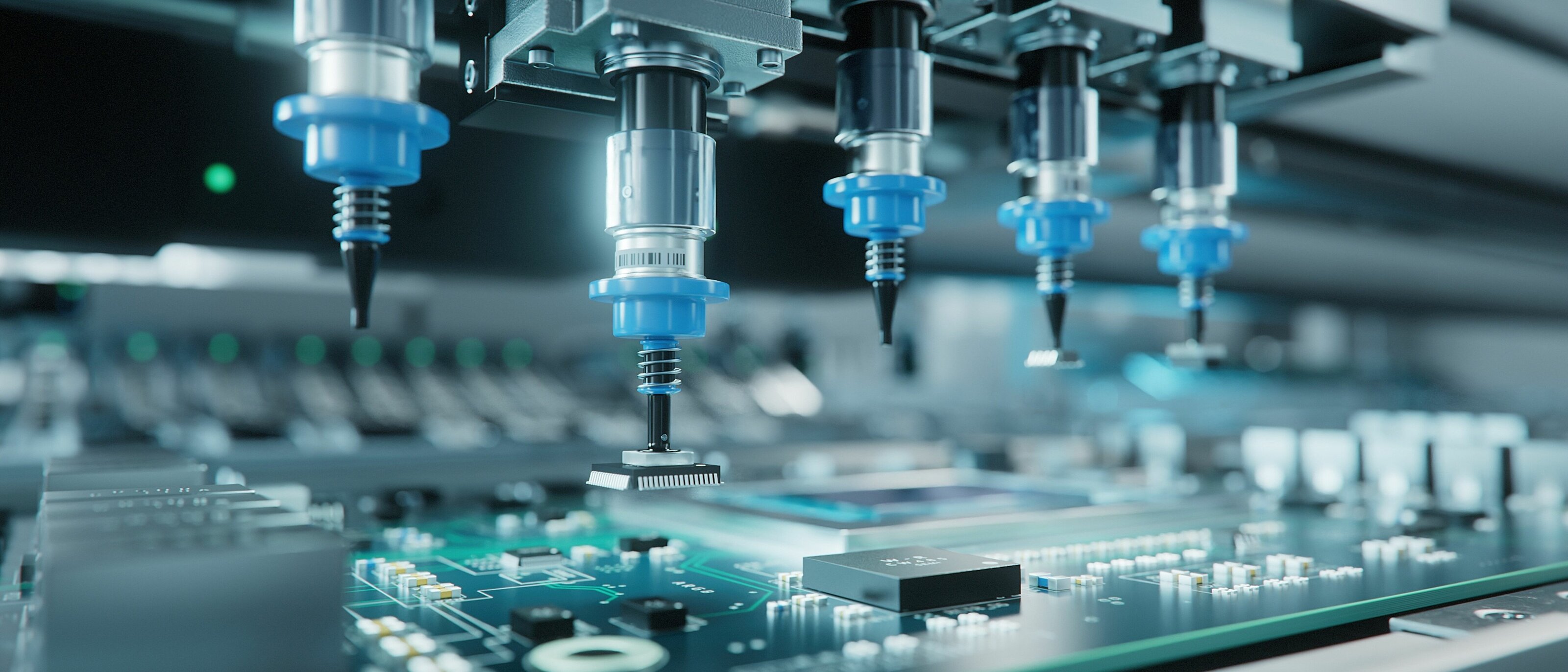

Production at SYS TEC electronic is a great example: With the help of Wirepas technology, employees can monitor the temperature and humidity in their production, which is critical for the manufacture of their products. They can do this remotely and over a long period of time. This way, they notice in time if, for example, the air conditioning system fails. Consequently, the SYS TEC electronic team can react quickly and prevent production from coming to a standstill or producing rejects due to temperatures that are too high or too low.

What challenges exist in the IIoT?

From my experience, two challenges often play an important role.

First, these "things" that you want to network together usually speak different "languages." In a production hall, for example, it is often the case that there are a wide variety of machines with a wide variety of controllers that have different protocols. The breadth ranges from old to completely new. This heterogeneity must be reconciled and homogenized so that the "things" can communicate with each other and with people in one language and via one medium.

On the other hand, the issue of security plays a major role in many cases. When all "things" are networked via the "Internet," many are concerned that unauthorized persons will gain access to this data. Suitable mechanisms and technologies must reduce this risk to a minimum. For example, the cloud does not always have to be the storage location of choice; it is often sufficient for the data to be available locally, stored on a local computer and only accessible via the on-site plant network. Furthermore, modern encryption technologies, for example, can be used to secure the transfer of data and protect it from unauthorized access.

Where does the data for industrial apps come from?

As mentioned, this can be a wide variety of data sources. Be it the machine controls, the environmental data measured by sensors, existing systems such as databases, MES systems, etc., components that are tracked using RFID, or even the knowledge of people that is digitally recorded. For example, experienced machine operators usually know best the quirks of the machines and how they can easily fix them.

But there are so many other data sources. The use cases and associated data sources are very diverse. That's very exciting to experience when you're in the IIoT space.

What are the advantages of the cooperation between ELCO and SYS TEC electronic?

The advantages are obvious: SYS TEC electronic's hardware solutions are the basis of a powerful edge level including the connection of fieldbuses and the preprocessing or compression of data. Finally, ELCO's solutions are used for the cross-site and cross-system networking of production data and the determination of key figures. We are thus in a position to technologically serve the entire layer model of the IIoT and thus not only offer customers holistic solutions, but also implement new use cases based on Wirepas, for example.

Both of us have made it our task to homogenize data from a wide variety of sources and make it available to other systems for further processing. Specialized know-how, openness and a common goal make up the charm of our partnership.

Joint customers benefit from a convincing unit for the IIoT: the sysWORXX CTR-700 from SYS TEC electronic with the IoTHub from ELCO.