Our technologies used

SYS TEC electronic is a specialist for the development of customized products. Here, our know-how for the combination as well as integration of broadly diversified technologies is in the foreground. Due to this broad field of competence SYS TEC electronic is able to realize complex individual projects.

Automatic Optical Inspection (AOI)

Automatic Optical Inspection (AOI) is a separate form of visual inspection. Here, the components to be inspected are photographed with computer support and compared with the stored component via a component library. In this way, any defects in the components can be quickly identified.

Boundary Scan

Boundary Scan uses a standardized procedure to check assembled PCBs for correct components and soldering, for example. UnlikeICT testing, for example, this is done without direct physical access to the component. The boundary scan method uses latches with which signals can be injected from outside into the circuit under test via predefined paths.

BurnIn test

The BurnIn test is a stress test designed to determine the failure safety of parts, components and devices. These are subjected to high loads (e.g. temperature) over a longer period of time in order to test their quality. This can prevent subsequent failures during continuous operation.

CAN

The Controller Area Network (CAN) is an asynchronous, serial bus system for networking control units. CAN was developed to reduce the amount of cabling required when networking various control units and sensors. Communication via CAN is event-driven. This means that messages are sent when they occur.

Signal transmission in CAN is divided into two transmission types: CAN High-Speed and CAN Low-Speed. In contrast to CANopen, the physical properties are not specific to CAN.

CANopen

CANopen is a communication protocol based on CAN, which is mainly used in automation technology and in the field of commercial vehicles. It is also often used for networking within complex devices. CANopen supports various communication objects such as PDO (process data objects) for the transport of real-time data and SDO (service data objects) for the parameterization of object dictionary entries.

Condition monitoring

Condition monitoring is used to constantly monitor machines and systems. Various sensors record a wide range of physical parameters such as temperature, pressure, vibration and acceleration. The analysis of the data obtained in real time allows conclusions to be drawn about the current condition of the system. This is the prerequisite forpredictive maintenance.

Design to Cost

With design to cost, cost control begins during product development. The aim is to minimize overall costs, generate a lower time-to-market and produce very cost-effectively.

Design for EMC

Design for EMC is about creating anEMC-compliant electrical design already during the development of a product.

Design for Manufacturing (DFM)

Design for Manufacturing (DFM) is the adaptation of a product idea to the given conditions in production in order to save costs.

Design for Test

Already during the development of components and assemblies, the later test procedures must be thought of and taken into account in the layout as well as the circuits. With Design for Test it is possible to realize optimal assemblies for the respective tests.

E²MS

Electronic Engineering Manufacturing Services

Edge Computing

Edge computing is a distributed, open IT architecture characterized by decentralized processing power that lays the foundations for mobile computing and IoT (Internet of Things) technologies. In edge computing, data is processed by the device itself or by a local computer or server and is not transferred to a data center.

EMS

Electronic Manufacturing Services

EMC standard

Electromagnetic compatibility (EMC) indicates whether devices and systems function without having a negative influence on their environment and other devices and systems. EMC is therefore considered an important quality feature.

First Article Inspection (FAI)

First Article Inspection (FAI) is the initial sampling of components. This involves checking whether they meet the properties specified by the customer. The supplier/producer thus provides proof of the quality of the manufactured components.

First Pass Yield (FPY)

The First Pass Yield (FPY) is a fixed indicator in the course of quality management and represents a measure of the quality of processes. It indicates the sum (in %) of components/groups that have been produced without defects after the first production pass. SYS TEC electronic achieves an FPY of 99.9 %.

Failure Mode and Effects Analysis (FMEA)

Failure Mode and Effects Analysis is an analytical reliability analysis. It is used to evaluate potentially occurring faults as early as possible (e.g. in the design phase) with regard to their probability of occurrence and detection. In this way, possible component faults can be detected and avoided beforehand and costs can be reduced.

Field Programmable Gate Array (FPGA)

Field Programmable Gate Arrays (FPGAs) are freely programmable, reusable chips for circuits whose function can be defined by the user. This enables the uncomplicated implementation of hardware functions without circuit boards and soldering work. FPGAs are considered to be very powerful, reliable and flexible.

Graphical User Interface (GUI)

The Graphical User Interface GUI represents the user interface of a computer. By means of graphical symbols and control elements such as icons, buttons, toolbars and sliders, the existing software is to be made operable and usable.

Human Machine Interface (HMI)

A Human Machine Interface (HMI) is a device or software that allows the user to communicate with machines or production equipment. The HMI is used both to display process and production data and machine statuses and to enter user data or operator commands. This provides the user with all the necessary tools to control the processes.

High Voltage Test (HV Test)

The HV test checks the effectiveness of the electrical insulators of the current-carrying conductors and the safety distance to the device housing.

In-Circuit Test (ICT Test)

The in-circuit test (ICT) is an electrical test procedure for electronic assemblies and assembled printed circuit boards. The focus here is on component parameters. The assembled PCB is placed on the test fixture with thin test needles and then tested for defects in the conductor path, such as soldering defects, assembly defects or short circuits. Analog parameters (inductance, resistance, etc.) are measured.

IP protection classes (International Protection)

According to the DIN standard, the IP protection classes define the extent to which a component can be exposed to various environmental influences without being damaged or posing a risk to the safety of the devices. The components are classified here by means of two code numbers - protection against contact and foreign bodies and protection against water. Numbers are used to identify the different grades.

LabVIEW (Laboratory Virtual Instrumentation Engineering Workbench)

LabVIEW is a graphical programming unit for data processing as well as data acquisition, whose main fields of application are measurement, control and application technology. The programming language used is G.

LPWA Network (Low Power Wide Area)

LPWA is a networking technology in which very small amounts of data are transmitted wirelessly. LPWA networks are very popular for smart device communication due to their low power consumption, very long range even in difficult terrain, and low material costs (see alsoNarrowband).

Meshnet

A meshnet is a spontaneous, flexible wireless network that connects to each other through nodes.

Mean Time Between Failure (MTBF)

The MTBF stands for the mean time between two failures. It measures the reliability and availability of devices and provides a basis for safety and reliability analyses.

Message Queue Telemetry Transport (MQTT)

MQTT is an open messaging protocol for M2M communication in the sense of Industrie 4.0 and is now one of the standard protocols for the Internet of Things.

Narrowband

Narrowband belongs to the LPWA networks and is a standardized radio technology that is particularly suitable for M2M communication. This narrowband communication is therefore very important, especially for IoT (Internet of Things) and is used, for example, in the field of Smart Industry, Cities & Buildings.

Node-RED

Node-RED is one of the programming tools of the Internet of Things (IoT). It is based on the data flow programming method (graphical representation of the data flow). The program works with prefabricated function blocks that facilitate the connection between IoT device and IoT platform.

Peak Shaving

The lowering and thus balancing of peak loads is also known as peak shaving. It is used to avoid supply bottlenecks at times of particularly high demand for electricity, to save costs, to reduce the load on the grid and the power plant fleet, and to make more efficient use of resources overall.

Predictive Maintenance

Predictive maintenance means predictive maintenance. In the course of Industry 4.0, it is becoming increasingly important to be able to predict possible failures and malfunctions in order to avoid costs for downtime and unnecessary component replacement. Predictive maintenance allows conclusions to be drawn at an early stage about possible maintenance requirements and future malfunctions with the help of data obtained throughcondition monitoring.

RAMS (Reliability, Availability, Maintainability, Safety)

Reliability, availability, maintainability and safety are summarized for RAMS as a concept bundle, which is based on the DIN standard EN 50126. RAMS represents a process that is intended to prevent subsequent faults as early as the planning phase of new products. This includes risk analyses, tests and safety verifications as well as hazard rates. RAMS is used primarily in the rail industry.

Second source method

The aim of the second source method is to always have one or two alternative suppliers for a product or component. This is to prevent supply bottlenecks, overpriced products and unavailability.

Safety Integrity Level (SIL)

The Safety Integrity Level (SIL) belongs to the field of functional safety and indicates the reliability of safety functions by means of a risk assessment (integer values from 1 to 4). The respective SIL results in functional as well as safety-relevant specifications for the components and devices, which must be complied with during design.

Programmable Logic Controller (PLC)

A programmable logic controller (PLC) is a device for controlling machines and systems. A PLC works cycle-oriented according to the EVA principle (read-process-output). The international standard IEC 61131-3 defines 5 alternative languages for PLC programming (IL = Instruction List, ST = Structured Text, LDD = Ladder Diagram, FBD = Function Block Diagram, SFC = Sequential Function Chart).

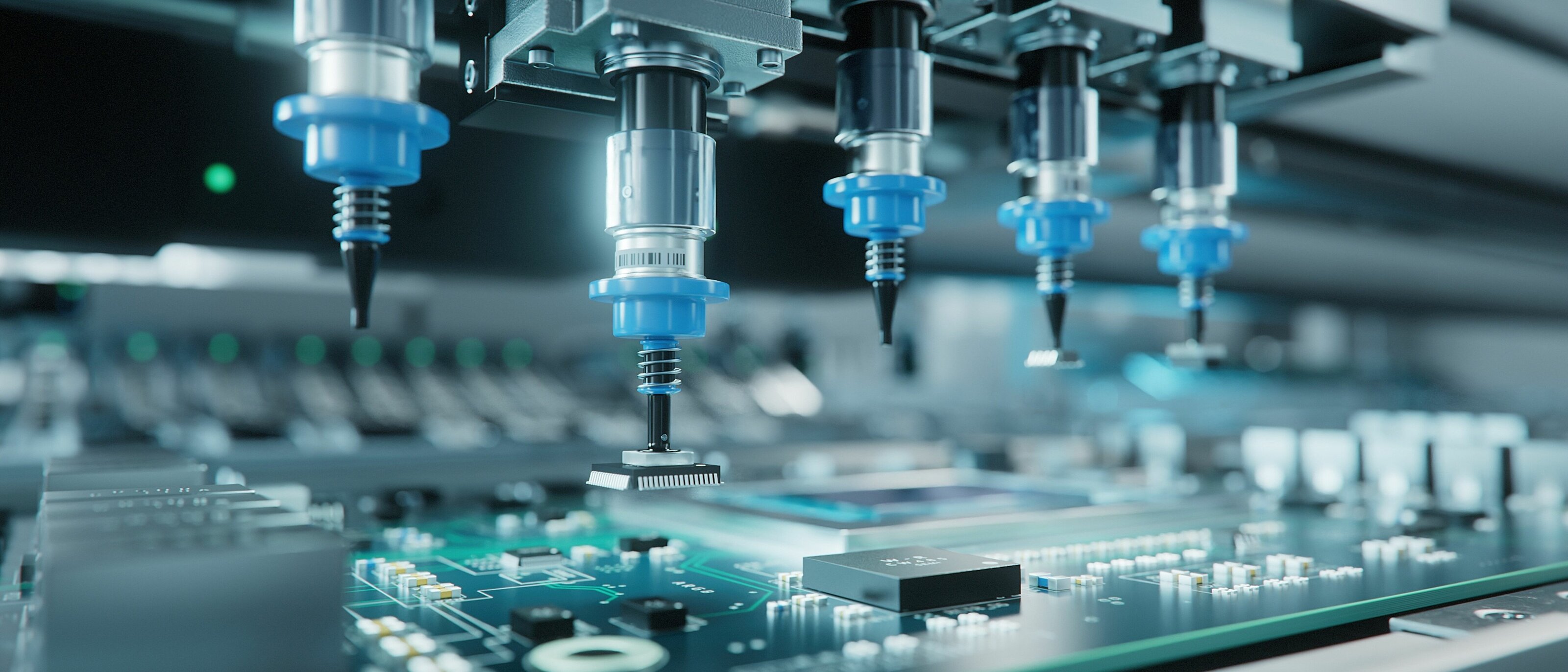

Surface Mounted Technology (SMT)

In surface-mounted technology, the components are assembled and soldered by machine or manually. The solder paste required for the soldering process is applied directly to the circuit board using a stencil. This is therefore a surface mounting process without wire connections, which does not require any drill holes and can use thinner boards. SMT assembly is a part of Electronic Manufacturing Services.

Through Hole Technology (THT)

Unlike SMT, through-hole technology involves a push-through technique. The wired components are inserted through the openings in the PCB and then soldered by hand or by machine.