Flexible, on-time, high-quality production of complex electronic assemblies

As an EMS service provider, we offer our customers from a wide range of industries a comprehensive service. The flexible and timely production of complex assemblies under the highest quality standards distinguishes us. From material procurement and logistics to device assembly and automated printing of your devices and systems, with label printing as well as sales packaging, we realize your product.

-

In our air-conditioned...

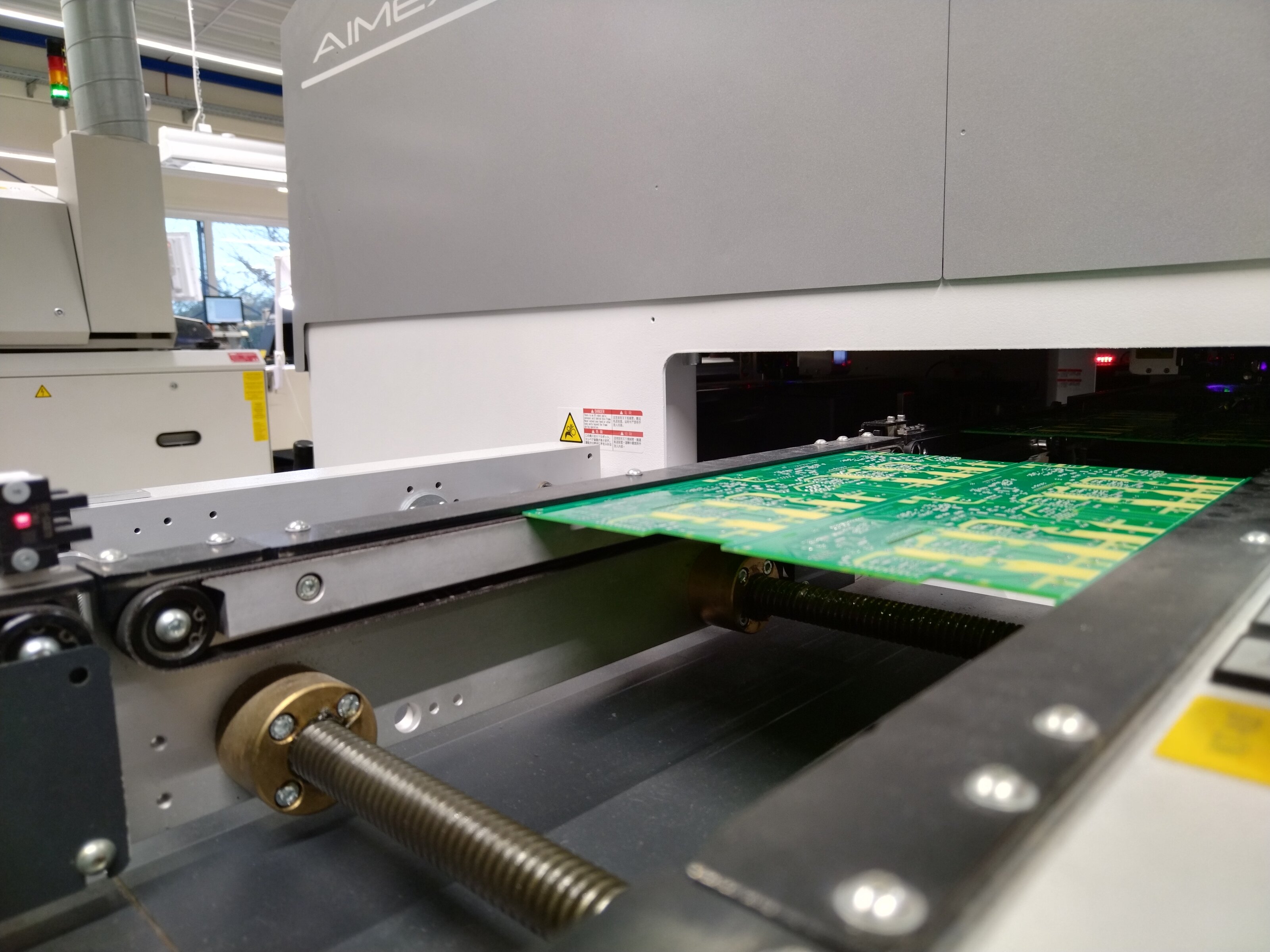

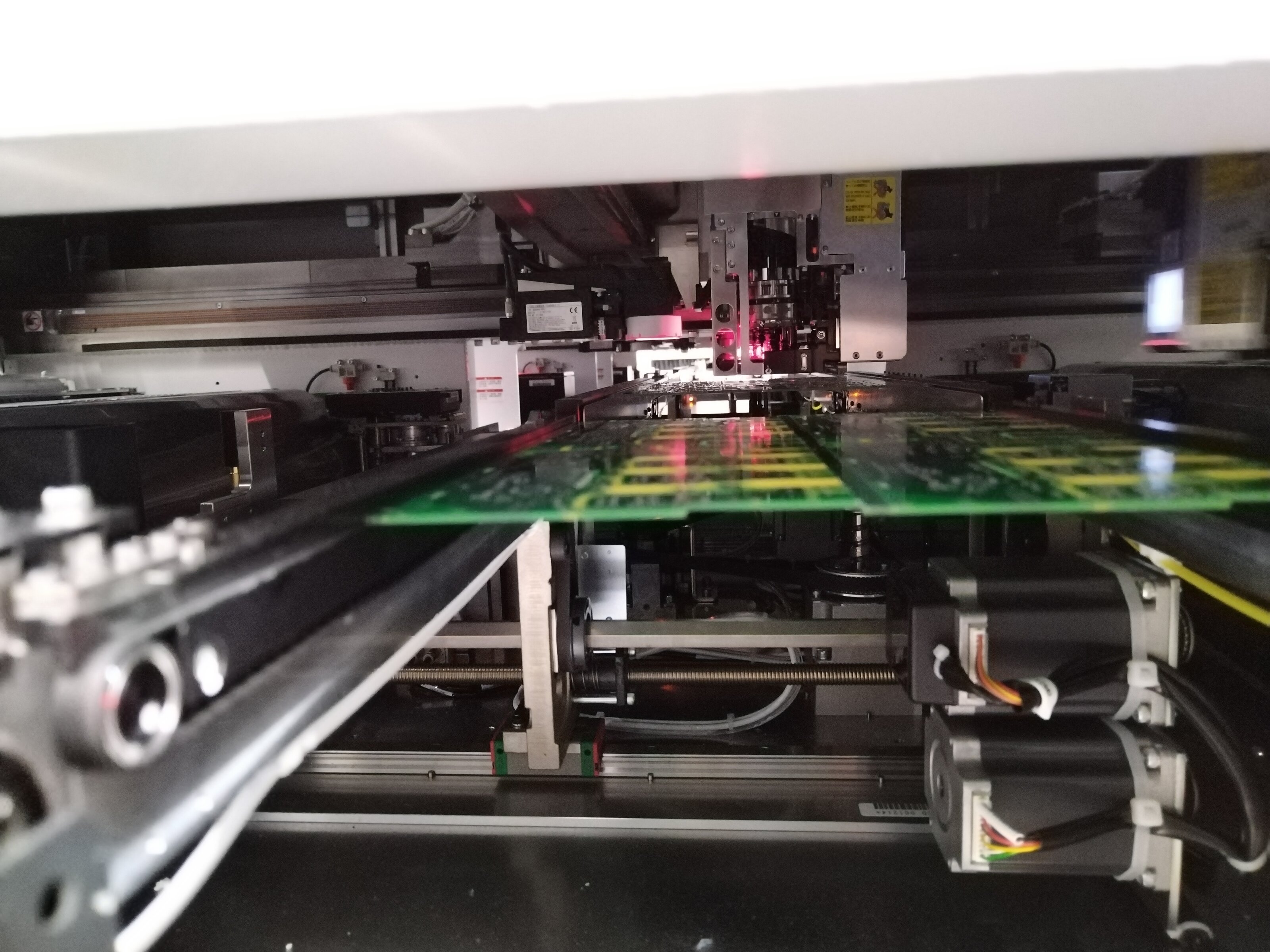

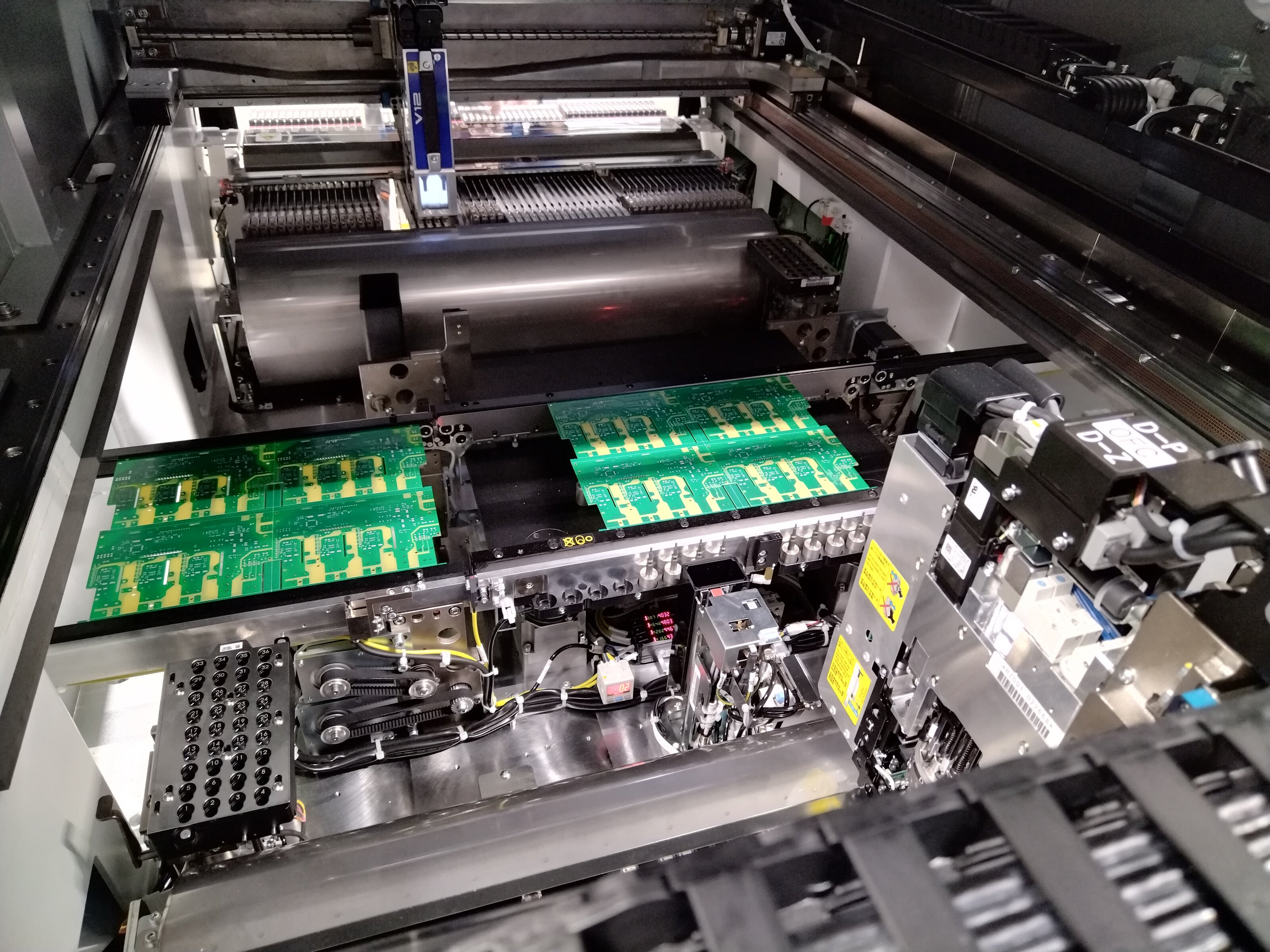

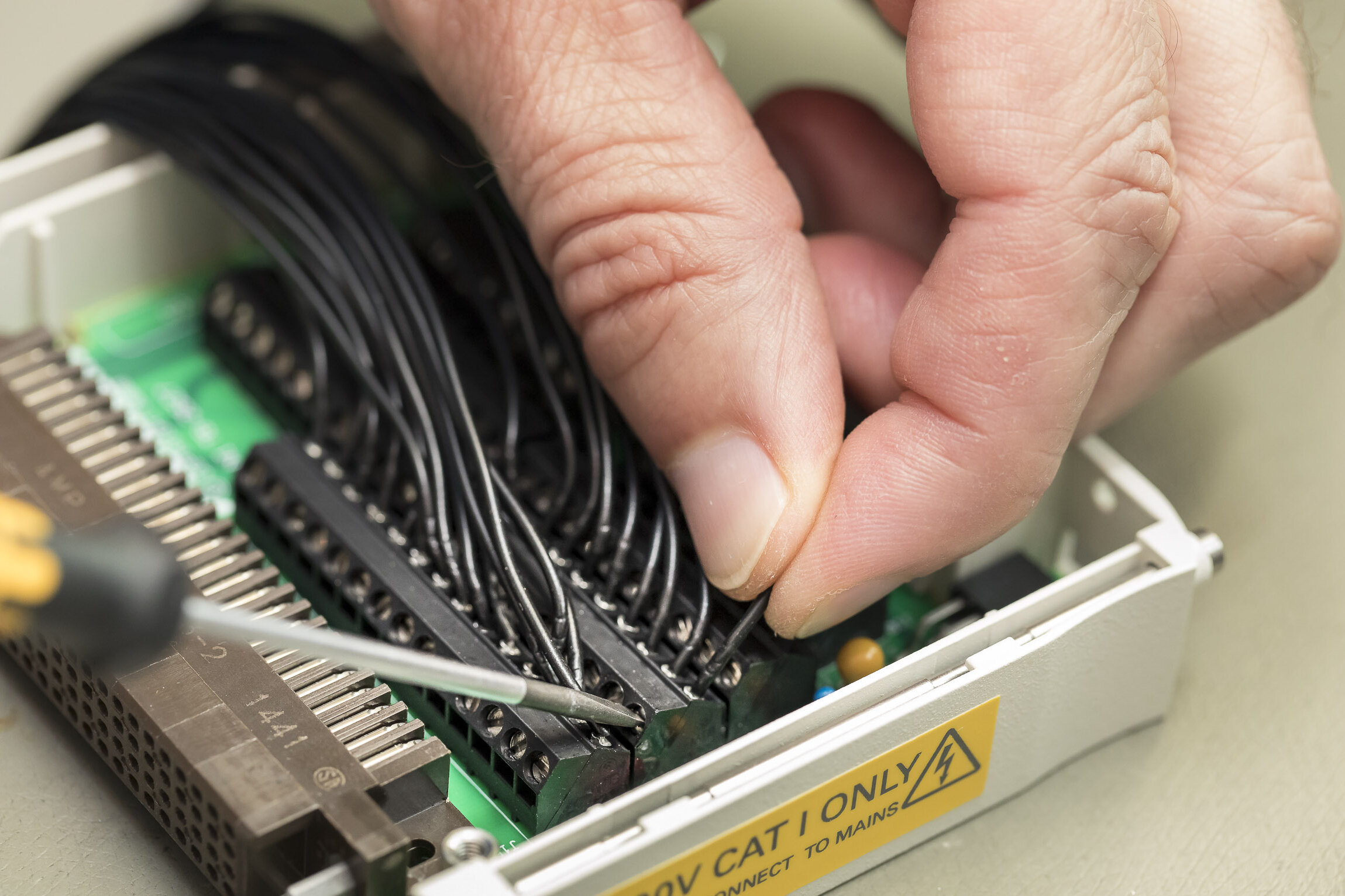

... ESD-compliant production, we manufacture assemblies according to your specifications. Precision in the assembly of printed circuit boards is ensured by our specialists, who realize, among other things, the operation of modern SMT assembly machines (Surface Mounted Technology), manual THT assembly (Through Hole Technology) and automated soldering. SMT components are processed on pure SMT boards or in mixed assembly with wired THT components.

-

Quality control...

... is an elementary component in every project phase at SYS TEC electronic. During the visual inspection by means of modern AOI workstations as well as X-ray diagnostics, the manufacturing quality of assembled/soldered components on the circuit board is assessed. By means of ICT test (In Circuit Test),Boundary Scan, HV test (High Voltage Test) and BurnIN test the reliable functioning is checked again. The final quality control, for example with First-Article Inspection (FAI), functional test and commissioning, is always carried out for all our assemblies.

-

The surface sealing...

... by lacquering and potting printed circuit boards are part of our comprehensive technology park for the protection of assembled printed circuit boards. These processes ensure the functions and properties of your electronic assembly under difficult environmental conditions and thus increase its service life.

-

Our serial production...

The performance spectrum in SMT assembly enables the assembly of designs such as 0201 and micro BGAs. For the wired components, the automatic selective soldering process is used, which enables reproducible solder joints of consistent quality. Nitrogen is used to support the soldering processes and to store moisture-sensitive components.

The flexibility of the production line allows the assembly of small quantities starting from one component (for example a prototype) with the series technology. In this way, the potential for optimum series production is already created at the prototype stage. Close liaison between the development engineers and the production engineers ensures that the design is suitable for production (design for manufacturing). Prior to electrical testing, visual inspection is performed with the support of an automatic optical inspection system.

The test scope can be completed according to requirements, with for example calibration or run-in (with temperature test chamber). Thanks to traceability, strict compliance with ESD standards and our specialized colleagues, the production is designed for all areas of electronics, from printed circuit boards to complex devices. This also applies to safety-relevant projects.

-

Relevant parameters...

- modern production conditions

- Traceability back to the manufacturer's batch

- storage of sensitive components and blanks under nitrogen

- paste printing with optical position control and automatic stencil cleaning

- SMD assembly up to 0201, µBGA, FinePitch from 0.3mm, up to 55x55mm size; output 20,000 BE/h, accuracy 0.035mm; intelligent feeders -> no mixing up of components

- maximum size of printed circuit boards in the standard process is 400x350mm

- processing of PCBs from 0.8mm thickness and aluminum core PCBs

- stress-free depaneling via milling machine

- flexible production starting from quantity 1 (prototypes)

- automatic selective soldering for reproducible solder joints at the THT components within complex SMT

- soldering process under nitrogen for leaded and unleaded components

- automatic optical inspection of each PCB by a flexible AOI system with combined 2D and 3D technologies

- functional test of each board, including calibration, burn-in (temperature test chamber), boundary scan and software installation

- Preparation of a design suitable for production through close linking of engineers in development and production

- direct access of the development engineers to production

- Support of products from development to prototypes and series production

- assumption of assembly service

- production of safety-related devices, also from own development according to class 3 IPC-A-610

- ISO-9001 certification, continuous ESD protection, full service from procurement to delivery

Your contact:

Your SYS TEC electronic sales team